Marine Transmission Oil Coolers Overview

Marine transmission oil coolers are NOT necessarily proprietary — they only have to meet the flow/heat rejection specs needed for the transmission, keep the gear oil at the proper (not to exceed) temperatures under worst case situations, AND fit the engines raw water circuit. (keep in mind, I am not talking about “coolant cooled” transmissions or oil coolers – different application)

Generally, when looking for a marine transmission oil cooler, it must meet or exceed the requirements that you need AND both Twin Disc & ZF specifications. In other words, a GOOD marine transmission cooler will have, at least, the following qualities:

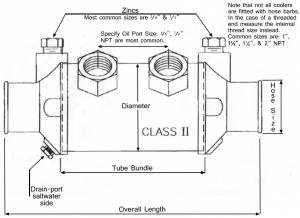

Constructed from a quality CU-NI (copper-nickel) alloy on the salt water side, all furnaced brazed using silver alloy solders designed for “High-Pressure” , usually called “Class II” with operating pressures of 300-500 PSI even if the transmission has lower operating pressures. This means that the cooler is “stronger” in all respects and will hold up to more abuse. Cast bronze end caps and oil lugs or “saddle” fittings. No wrought copper or sheet metal. Provisions for as large a zinc(s) as practical.1/4″, 3/8″ and 1/2″ standard zincs are most practical. The unit is sized internally and externally for the application- in other words it “fits” where it is supposed to fit.

If you are reading this, it could very well be because you have damaged a marine transmission because of a cheesy gear cooler failure. In my opinion, many transmission oil coolers that come on new engines from today’s name brand engine companies have no place on a marine engine. One, the engine OEM’s typically use the cheapest cooler that barely meets the specifications needed, and two, most companies supply a transmission that is marginally rated for the application and then size the cooler for that smaller marine gear.

Common Problems & Understanding them

SYMPTOM ONE of a serious issue: If you have gray or cream colored oil in your gear, you have a failed gear oil cooler. Very simple. You need to flush out the gear–Just take the oil lines off the cooler and attach them together by-passing the cooler and do a couple of oil changes–Use SAE 10 or 20 wt to flush at the dock.. Be sure you bump it in gear, both FWD & Rev for flushing out all of the old oil from the clutch packs.

SYMPTOM TWO of a possible serious issue: If you see oil dots or a rainbow all of a sudden behind you vessel at the wet exhaust outlet, STOP and check you transmission oil.. This is usually the first symptom of a failing gear oil cooler, but sometimes you are not so lucky to see this.

SYMPTOM THREE can sometimes be caught while driving the vessel. This may show by the engine(s) revving up but the vessel is slowing down (clutch slippage) or in a twin engine boat, all of the sudden the boat starts turning opposite the slipping transmission. Both of these require the operator to take immediate action so more damage is kept to a minimum…

We can supply most any sized transmission oil cooler and stock over 100 different types of cooler at any given time. If you are unsure of the size of your cooler, click the image to the right to see an expanded diagram of “How to Measure” your transmission oil cooler properly, or feel free to email us with a photo of what you want to replace. We’ll sort it out for you.