Description

SMX PURPLE Specialty Vibration Isolator — “The Story”

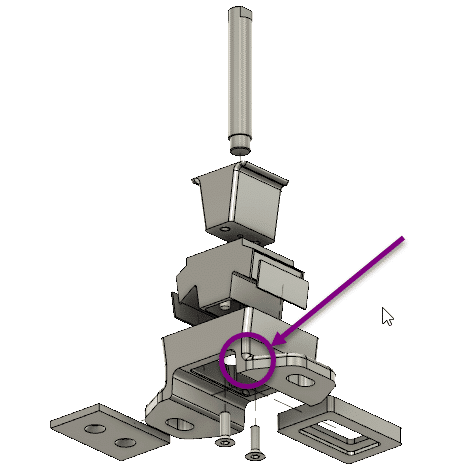

The first truly “tune-able” and fully “rebuildable” Marine specific engine isolator to meet the needs of modern high speed diesel light weight engines used in marine applications.

The first truly “tune-able” and fully “rebuildable” Marine specific engine isolator to meet the needs of modern high speed diesel light weight engines used in marine applications.

These were specifically designed isolators to fit not only many Cummins mid-range engines but all other marine diesel engines in the 100-500 HP class with total engine / transmission weights totaling 2600 lbs or less. From 4 cylinder “shakers” to the smooth, but heavy CAT 3208’s and everything in between.

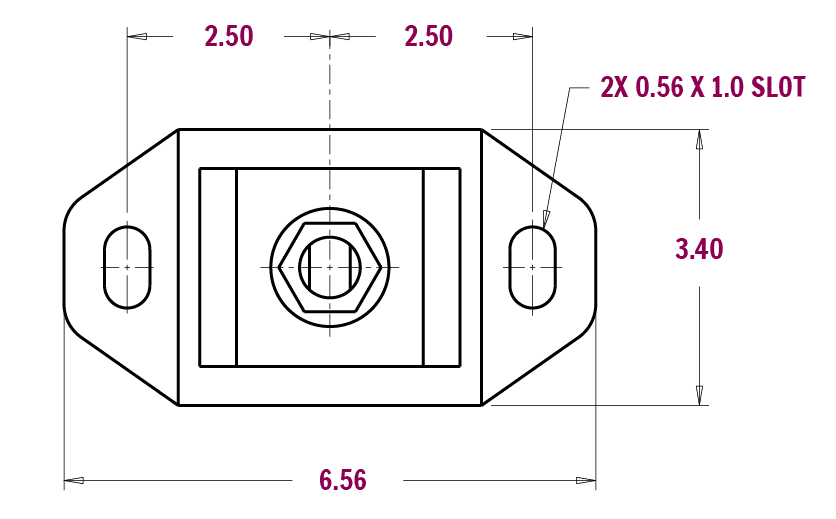

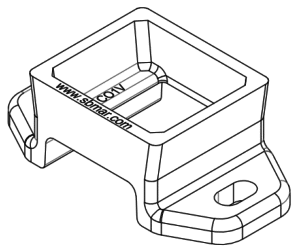

Our base mount footprint and “look” was patterned after the famous “Barry” B series mount (Cummins P/N: 3349230) that came into the market about 1994-ish and has shown to be the an excellent product over the years. Although the isolation qualities of the mount were excellent in many cases (not all), the adaptability of the mount left many gaps in where it could not be used successfully. The mount had a limited weight range, was not really “right” for the “shaker” 4-cylinder Cummins engines (and some “others”), and could not fit nor carry the weight of 1000’s of the V-8 Diesels that were out in the field sitting on the very old “Bushings Inc.” mounts with both ¾” & 1” studs, and did not adapt well to remote mount V-drive applications where extra engine isolation is needed.

These were our first concerns on our list of new design features we wanted to address. But along the way, we were also able to accomplish the following improvements:

FEATURES THE MOST EFFECTIVE REDUCTION OF NVH (NOISE, VIBRATION, HARSHNESS) available for INTERNAL COMBUSTION DIESEL ENGINES IN MARINE INSTALLATIONS — Some of our unique engine mount features include:

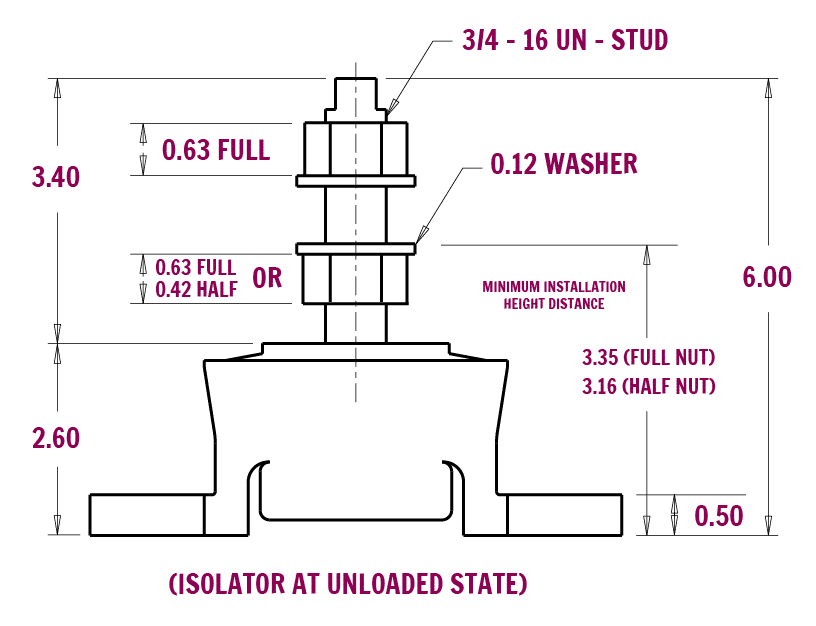

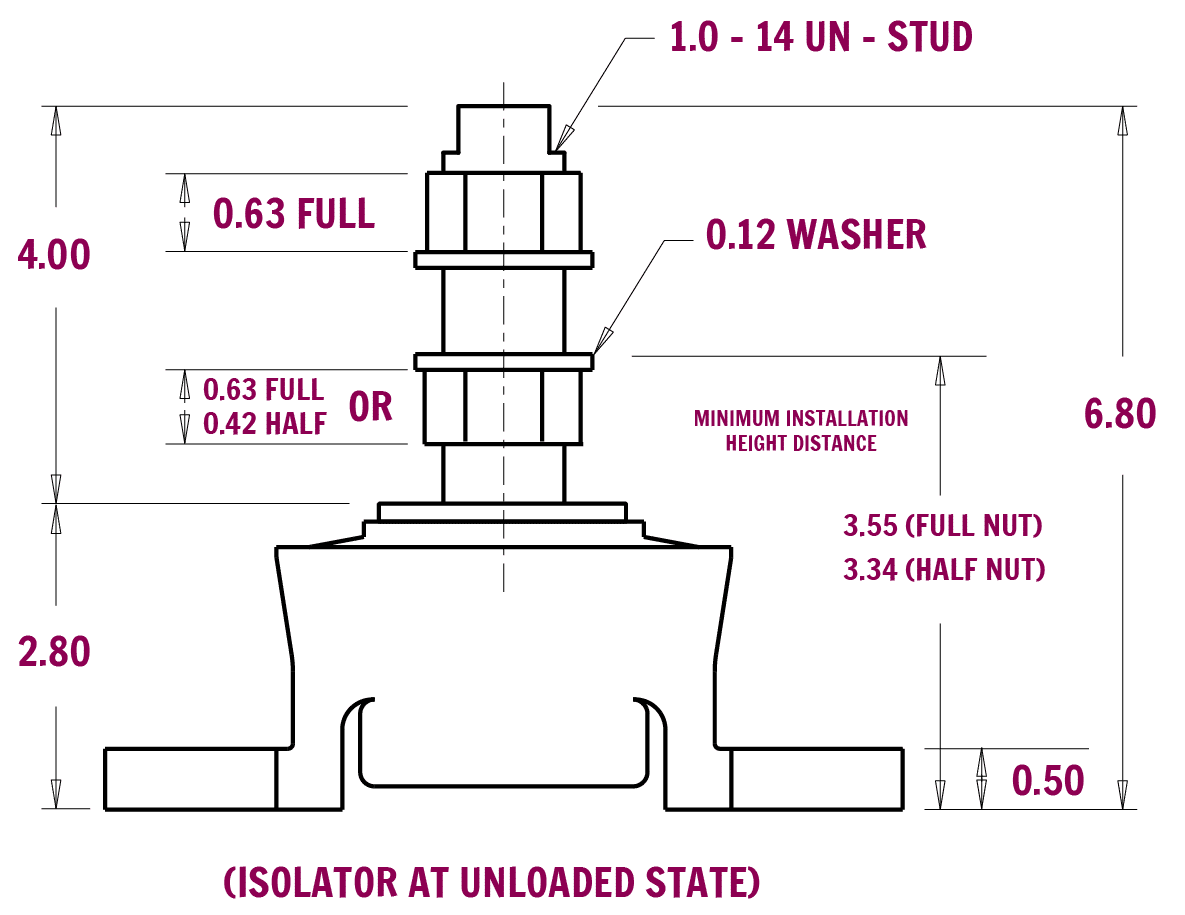

Our “SMX PURPLE″ mount comes in 7 Durometer versions and in 2 stud size options, chosen specifically to your exact application.

Choose from 7 available durometers…

Best suited for engine/transmission installations that want extra stability, especially in applications with large (deep ratio) transmissions. QSB 5.9 Pleasure Duty with Aluminum Transmissions

(Typical 6BTA 300, 315, 370 with a ZF 220A or ZF 85A gear) with improved specifications available at a much lower overall cost.

Best for engines similar to 6BT 5.9 210 with a heavy duty engine/gear package. (~1500 lbs packages).

Best for engines similar to 6BT 5.9 210 with a ZF 63A or other engine/gear packages that are similar (1200- 1500 lbs packages).

We built this version to address lower HP/lighter weight diesels, inline 4-6 cylinder applications with package weight up to 1200 lbs. Examples include a 4BTA, 6B (naturally aspirated), Perkins 6-356, Ford Lehman 120, etc.

Specifically made for the Cummins 4B (naturally aspirated) and other “not so nice to be around” 4-cylinder engines, or for remote non-thrust engine application weighing up to approx. 1200 lbs. For all Close coupled v-drive applications heavy duty commercial, best to call and ask for Tony if you are not sure what mount is best.

Features & Benefits…

- Mechanically captive

- Resilient elements of an oil-resistant newly developed synthetic Chloroprene compound

- Corrosion resistant exposed metal parts

- Off-the-shelf availability

- Easy to install as the are the same foot print and dimensionally interchangeable as the Barry Cummins mount they replace

- SMX 100% long term Proven durability

- Easiest Load & Height adjustability available

BENEFITS

- Improved ride comfort

- Significantly reduces mechanical noise transmission

- Able to transmit propeller thrust longitudinally along mount

- Superior isolation at start-up and low RPMs

APPLICATIONS

- Marine Diesel Engines

- Pumps

- Compressors

- Generator Sets

LOAD RANGE

- 5 versions with multiple load ratings from 100 – 700 lbs per mount

ENVIRONMENTAL DATA

Synthetic Chloroprene elastomer has an operating temperature range of -20°F to +180°F (-30°C to +85°C) and is resistant to oils, salt spray, ozone and oil-based solvents.